- The Outdoors Crowd

- Posts

- CubCrafters (1980), company history deep-dive

CubCrafters (1980), company history deep-dive

Plus; Social Listening - what’s the outdoors community talking about?

Hey, Outdoors Crowd.

Delighted to be back after a couple of week’s hiatus. Lots of moving parts here, which I’ll get into over the next few weeks.

This week:

Social Listening - what’s the outdoors community talking about?

CubCrafters: How a Backcountry Dream Took Flight

PS - if you’re new here or have been forwarded this email, you can read previous posts and sign up for the newsletter here: https://dereksdeepdive.beehiiv.com/

And please share if you like what we do. It helps enormously to drive down our cost or reader acquisition.

"Of all the paths you take in life, make sure a few of them are dirt." John Muir

1. Ultralight panic — when LighterPack went dark.

For a few hours last week, the ultralight community collectively lost it when LighterPack’s SSL certificate expired, briefly taking the site offline. Reddit threads lit up with backup spreadsheets and “plan-B” chatter. The takeaway? Trip-planning tools are becoming mission-critical infrastructure for hikers and guides — and there’s a real gap for a reliable, paid, pro-grade gear-planning platform with proper uptime and data export.

2. Fabric debates return — 10D vs. 15D and the X-Mid learning curve.

The latest r/Ultralight thread (mid-October) reignited the old tension between ultralight durability and usability. Campers compared 10D and 15D fly fabrics, while others admitted they need “practice pitches” before trusting their new X-Mid shelters. For brands, that’s free feedback: customers want transparency on materials and simple setup education. “Practice-pitch” content and laminated setup cards would go a long way toward reducing returns.

3. Yosemite confusion — permits, closures, and chaos.

Across Facebook and Reddit hiking groups, October hikers were still trading notes on Yosemite’s permit rules and fall closures. Many were unsure which trailheads required paperwork or how to adjust when the park tightens access. The opportunity? Retailers and outfitters can become trusted resources by offering up-to-date permit explainers and shoulder-season gear checklists. The community clearly wants information, not just equipment.

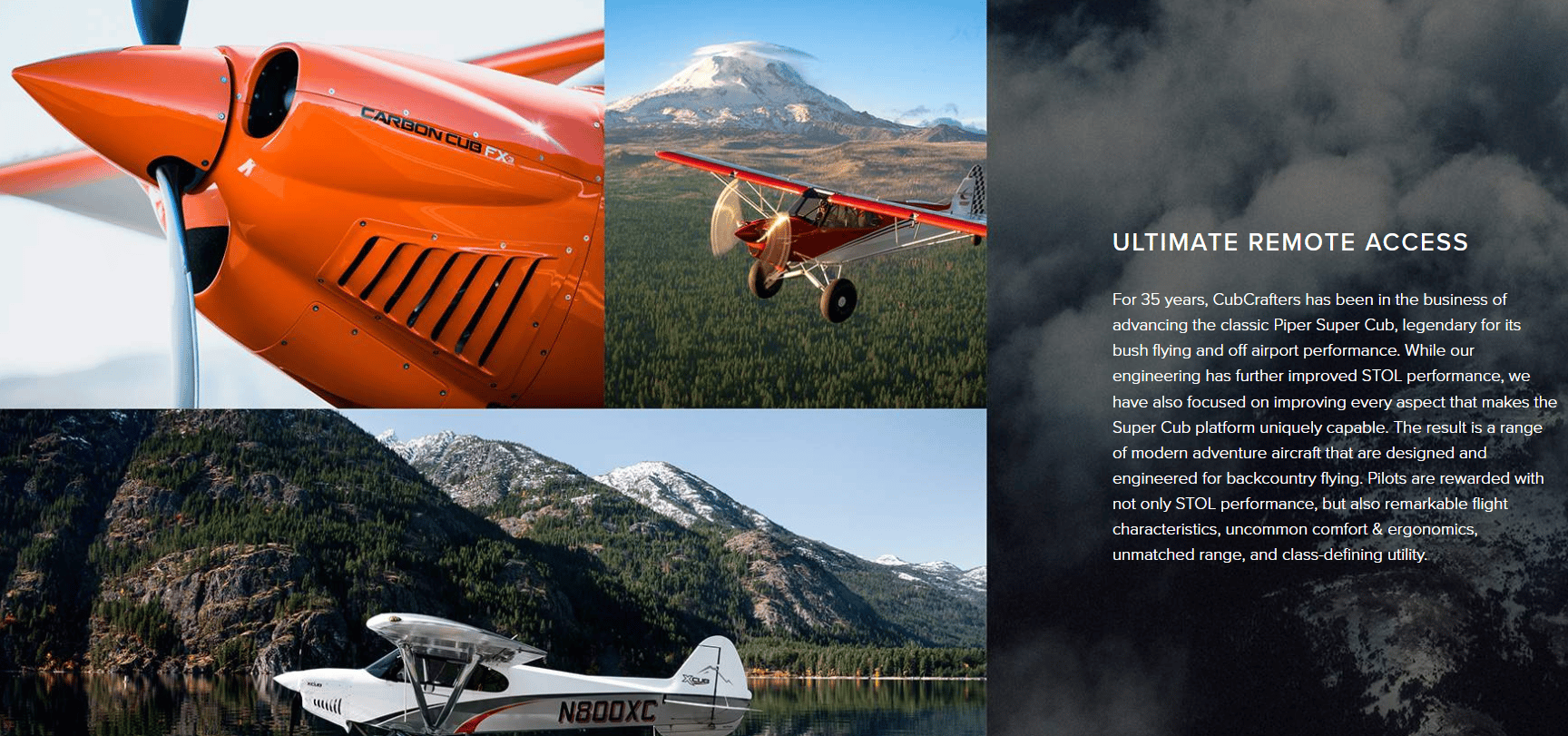

CubCrafters: How a Backcountry Dream Took Flight

If there’s one company that captures the soul of adventure aviation — and the grit of American manufacturing — it’s CubCrafters.

From its hangar in Yakima, Washington, this small-but-mighty aircraft builder has spent four decades crafting planes that can land where roads don’t exist — gravel bars, glaciers, and high mountain meadows. It’s the kind of brand that appeals equally to bush pilots, explorers, and dreamers who never outgrew the urge to take off.

And behind it all is a founder who started with an obsession, not a business plan.

A Pilot with a Toolkit

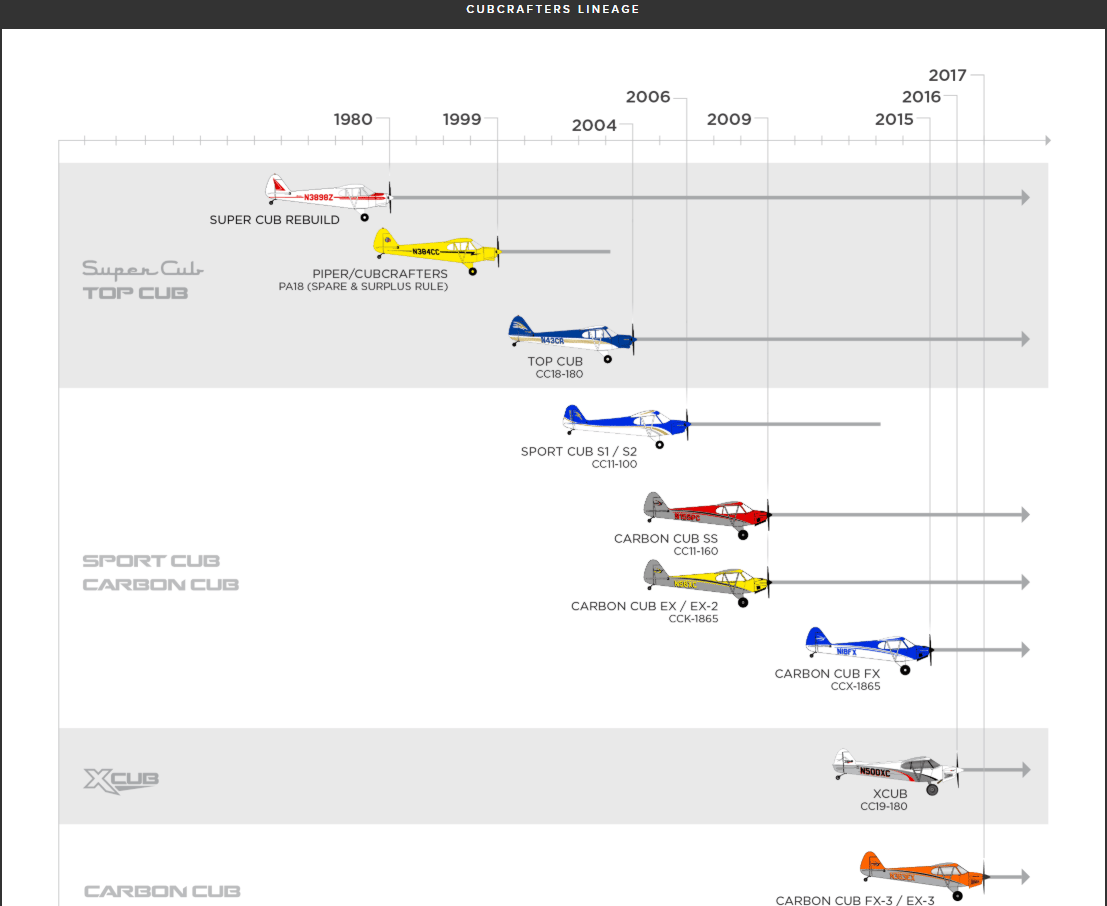

The story begins in 1980, when Jim Richmond, a young mechanic and pilot, started tinkering with Piper Cubs in a rented hangar. The original Piper PA-18 Super Cub — a simple two-seat taildragger designed in the 1940s — was beloved by Alaska bush pilots but long out of production.

Richmond saw a gap: people wanted new Cubs, but none were being built. So he started rebuilding them — better. Stronger airframes, lighter materials, upgraded engines. Word spread among pilots who actually used their planes to get places — hunters, guides, surveyors.

By the late 1980s, CubCrafters wasn’t just restoring planes; it was designing its own.

Building a Better Cub

In 1999, after two decades of perfecting rebuilds, Richmond launched the Top Cub, a certified aircraft that captured the feel of the original but met modern FAA standards. That was a huge step — going from “hot-rod mods” to full aircraft manufacturing meant new facilities, tooling, and certifications.

By 2004, CubCrafters had become the name in backcountry aviation. Its aircraft weren’t luxury toys — they were tools of freedom. But they were also beautifully built tools: hand-riveted aluminum, carbon-fiber touches, immaculate interiors.

The 2010s saw innovation accelerate. The Carbon Cub became the company’s signature model — a lighter, faster, more powerful evolution that married nostalgia with cutting-edge materials. The Carbon Cub SS, FX-3, and NX Cub pushed performance limits, with engines delivering over 180 horsepower in planes that could take off in under 100 feet.

When other light-sport manufacturers went fully composite or automated, CubCrafters doubled down on craftsmanship. Each aircraft is still built largely by hand in Yakima.

From Hangar Passion to Industry Player

By 2020, CubCrafters had quietly grown into a mid-size manufacturer employing roughly 150 people, producing around 100 aircraft a year.

The company’s planes aren’t cheap — most start around $350,000, and custom builds can exceed $600,000. That pricing reflects the labor intensity and quality — but also the fact that CubCrafters sits in a market with almost no direct competition.

Revenue for 2024 reached $40.7 million, with a small profit of $349,000, compared to $43.4 million in 2023 and a prior-year loss. That’s tight but steady performance for a niche aviation brand that manufactures everything in-house.

The Crowdfunding Offering That Turned Heads

Given our own background, I love this.

In November 2022, CubCrafters opened a multi-path public offering to everyday investors under Regulation A, CF, and D — the first of its kind in general aviation.

Over the following year, the company raised about $5.1 million gross before closing the offerings in January 2024. Shares were offered at $5.00, later adjusted to $5.45. Min investment was $400. I did take a look and it seems the website is still taking details from potential investors (analysis only - never investment advice).

Rather than a traditional IPO, it was a grassroots capital raise that let customers, pilots, and fans become partial owners — the same people who actually fly the product.

The proceeds funded expansion of production capacity, development of lighter composite structures, and R&D toward hybrid-electric propulsion.

Analysis only - never investment advice

Passing the Torch

Richmond passed away in November 2021, aged 67. Leadership had already been transitioning to Patrick Horgan, a veteran of Boeing and Cessna, who became President in 2018 and CEO in 2021.

Horgan kept the company independent, Yakima-based, and firmly anchored in its craft ethos, while adding structure and long-term planning. His team includes Brad Damm, Vice President overseeing sales and brand.

CubCrafters today remains a closely held private company — no mergers, no acquisitions — focused on organic growth and owner loyalty.

Innovation in a Sky of Giants

CubCrafters’ edge has always been its willingness to reinvent simplicity.

Milestones include the Top Cub certification in 2004, the NXCub nose-wheel configuration approved in 2020, and the forthcoming Carbon Cub UL, a Rotax 916-powered ultralight derivative with first customer deliveries scheduled for Q2 2025.

The company also announced XCub/NXCub kit programs in mid-2025, extending its reach to homebuilders and experimental aircraft enthusiasts.

And in its R&D hangars, engineers are testing electric-assist propulsion in partnership with innovators like Ampaire — aiming to bring hybrid flight to backcountry operations.

Financial Snapshot

2024 Sales: $40.7 million

2023 Sales: $43.4 million

2024 Net Income: $349 k profit

Employees: ≈150+

Annual production: ~100 aircraft

Ownership: Private, shareholder base from 2022–24 Reg A + CF + D raise

In an industry where few small manufacturers stay profitable, CubCrafters’ discipline, quality control, and direct relationship with its customers make it an outlier.

Why It Worked

Stay close to your user. Richmond built the plane he wanted to fly, and that authenticity runs through the company.

Premium over volume. The brand never chased mass production — it chased excellence.

Turn customers into investors. Crowdfunding made owners literal stakeholders.

Plan succession early. Transitioning leadership before the founder’s passing kept momentum and culture intact.

What’s Next

Demand for adventure aviation remains robust — especially among pilots chasing the freedom to “land anywhere.” Challenges remain: certification costs, supply-chain pressure, and the need to modernize propulsion.

But if history is a guide, CubCrafters will keep flying higher. Its blend of authenticity, craftsmanship, and controlled ambition has already turned a one-hangar dream into one of the most respected small manufacturers in America.

Lessons for the Outdoor Industry

You don’t have to be big to be significant.

Community ownership can replace outside capital.

Craftsmanship scales when the mission stays clear.

Like the aircraft it builds, CubCrafters proves that when design, passion, and precision align — you can take off from anywhere.

By the way, if you enjoyed this you may also like to read our article on Piper Aircraft

As usual, thanks for reading and I hope you find value in the newsletter. If you do, please share. It helps a lot. Also feel free to reach out directly with any thoughts or feedback (or interests in sponsoring / partnering) at [email protected]

Happy camping.

Until next week, go n-éirí leat!

Derek.

Social Listening - This Week in Outdoor Trends